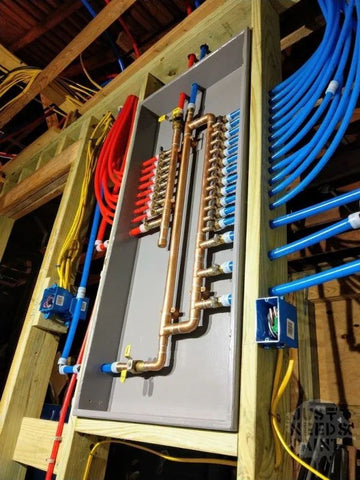

Because there are so many alternatives available, choosing PEX fittings for plumbing projects might be confusing. This thorough article explores the complex world of PEX fittings and clarifies the several kinds available. Each form of PEX fitting has a distinct function. Thus, any plumbing enthusiast or professional needs to understand these varieties. This pex fitting types guide will give you the knowledge you need to decide whether you're starting a new plumbing project or want to learn more.

1. PEX Crimp Fittings:

PEX plumbing is not complete without these fittings. They include a crimp ring installed with a crimping tool after being compressed around the PEX pipe. This establishes a tight and safe relationship. PEX crimp fixtures are obtainable in a variety of sizes and shapes to ensemble a diversity of pipe designs and diameters.

2. PEX Clamp (Cinch) Fittings:

Also known as cinch clamps, these fittings utilize a stainless steel pinch ring and a cinch tool for installation. They offer a reliable and adjustable connection, making them suitable for various PEX plumbing applications. The cinch method is popular for its simplicity and ease of use.

3. PEX Push-To-Connect (PTC) Fittings:

PEX push-to-connect fittings are designed for hassle-free installation without specialized tools. The fitting is pushed onto the PEX pipe for a secure connection. This type is ideal for DIYers who prioritize quick and tool-free buildings.

4. PEX Expansion Fittings:

Expansion fittings involve the expansion of the PEX pipe using an expansion tool. The fitting is then inserted, and a secure connection is formed as the pipe contracts. This method is known for its reliability and durability.

5. PEX Sweat (Copper) Fittings:

These fittings make the connection between PEX and copper pipes. Because of the sweat connection, plumbing projects can benefit from flexibility when switching from PEX to conventional copper piping systems.

6. PEX Compression Fittings

When constricted, compression fixtures threaded nut and compression ring provide a tight seal. They labor well for PEX-to-PEX influences as well as PEX-to-other pipe material changes.

Choosing the Proper PEX Fittings for Your Initiatives

It's significant to understand the different types of PEX fittings and their position in fashionable plumbing systems. Your selected PEX fittings greatly effect your plumbing organization's overall presentation, permanency, and competence. Here are some critical factors to take into account, highlighting the meaning of choosing the suitable PEX fixtures for your activities:

1. Corrosion Resistance:

PEX fittings have unsettled corrosion confrontation since they are chiefly collected of metal or plastic alloys. Associated to conservative metal fixtures, PEX fixtures are less susceptible to to rust and worsening over time. The pliability to corrosion improves the toughness and reliability of your plumbing system.

2. Flexibility and Expansion:

The PEX tubing's flexibility is one of the fittings' most notable characteristics. This flexibility eliminates the need for several connectors and fittings by making it easier to maneuver around obstacles. Furthermore, by accommodating the PEX pipes' natural expansion and contraction, the expansion fittings reduce the possibility of leaks or ruptures.

3. Economical Installation:

PEX fixtures offer inexpensive connection choices, particularly with push-to-connect and clamp fittings that do not necessitate exact instruments. Since PEX is easy to connect, it is a lucrative option for both professional plumbers.

4. Application Versatility:

PEX furnishings can be used for numerous projects, counting salable and housing plumbing. PEX fittings offer the flexibility required to grip multiple plumbing supplies, whether you're occupied on a large-scale building project or a small-scale restoration.

5. Compatibility with Various Pipe Types:

PEX fittings make swapping between pipe sorts easy. PEX's adaptability is mainly useful for including it into pre-existing plumbing arrangements since it enables unified connections with copper, PVC, and other materials.

6. Low Maintenance Requirements:

The inert nature of PEX materials decreases the probability of scaling, roughness, or other issues that might request frequent upkeep. This low-maintenance distinctive interprets to long-term savings and hassle-free plumbing processes.

7. Energy Efficiency:

PEX fittings subsidize to energy competence in plumbing systems. The lining possessions of PEX help uphold water temperature over lengthier distances, plummeting heat loss and endorsing energy conservation.

Here Are Some Tips For Choosing And Using PEX Fittings Effectively

Understand Your Project Requirements:

Prioritize a comprehensive understanding of your plumbing project. Different types of PEX fittings suit distinct applications, so knowing the specific needs of your project will guide you in choosing the appropriate PEX plumbing fittings.

Materials Matter:

Consider the material of the PEX fittings. Brass and poly-alloy fittings are common choices. Brass offers durability, while poly-alloy fittings are cost-effective. Evaluate the pros and cons to align with your project's demands.

Mind Your Budget:

PEX fittings come in a range of prices. Establish a budget for your project and choose fittings that balance cost-effectiveness with quality. Remember that long-term benefits such as durability and reduced maintenance may offset upfront savings.

Compatibility Check:

Ensure compatibility with your existing plumbing system. PEX's versatility is a strength, but it's crucial to confirm that fittings seamlessly integrate with other materials, like copper or PVC, if your system incorporates them.

Consider Push-to-Connect Fittings:

Push-to-connect fittings are user-friendly and require no special tools. They're ideal for DIY projects. However, verify their compatibility with your PEX tubing brand, as some systems may have specific requirements.

Evaluate Expansion vs. Crimp Fittings:

Depending on your project, choose between expansion and crimp fittings. Expansion fittings require less force during installation and result in a tighter seal. Crimp fittings, while effective, necessitate more force but are often more cost-efficient.

Prioritize Certified Products:

Opt for PEX connection types that meet industry standards and certifications. This ensures that the fittings comply with safety and quality benchmarks, providing peace of mind for your project's integrity.

Conclusion

In deduction, the efficiency, lifespan, and over-all health of your plumbing system are all wedged by the choice of PEX fittings, which drives beyond just connecters. Over careful deliberation of numerous fundamentals like fighting to corrosion, flexibility, affordability, compatibility, ease of conservation, and nominal maintenance supplies, you may improve the longevity and overall performance of your plumbing system.